Glass Cullet Handling Systems are available for manual and automated breakouts for cutting operations. These systems are designed to increase safety and reduce waste.

Benefits

- Increased Safety

- Less Handling of Glass Waste

- Reduced Forklift Traffic

- Improved Ergonomics

- Increased Dumpster Capacity

- Eliminates Waste

- Reduced Down Time

- Increased Production

- Adapts to Automated Outdoor Waste Collection

Step-by-Step Process:

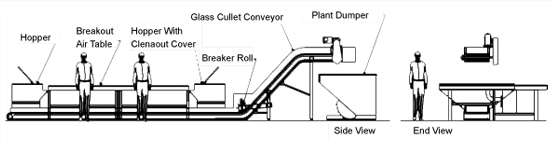

1. Glass Cullet Removed from Air Table:

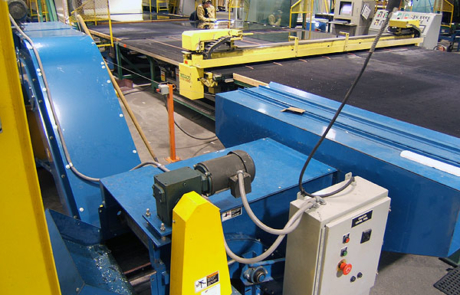

Glass cullet is removed from underneath the air table. This process eliminates the necessity of stopping the glass cutting operation for manual removal of glass cullet. This system is shown with manual cullet box and conveyor for cullet disposal.

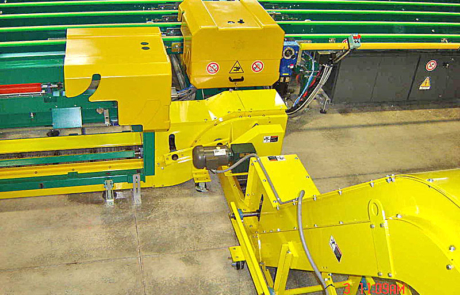

2. Glass Cullet Crushed by Breaker Roll:

Glass cullet breaker roll is used to crush glass into smaller pieces for transportation to hopper or plant dumpster. The small crushed cullet takes up less hopper and dumpster space.

3. Glass Cullet Transported by Conveyor:

Glass cullet is transported on steel hinged belt conveyor for disposal. The conveyor is rugged and reliable. This system is shown with multiple air tables, multiple breaker rolls, a long transportation line, and an incline.

4. Glass Cullet Disposed into Dumpster:

Glass cullet is disposed into a hopper or plant dumpster.

Photos

Literature

- Breakout Air Table Hoppers

- Glass Handling Conveyor

- Glass Breaker Roll

- Plant Hopper

- Glass Manufacturing

- Window Manufacturing